Price on request

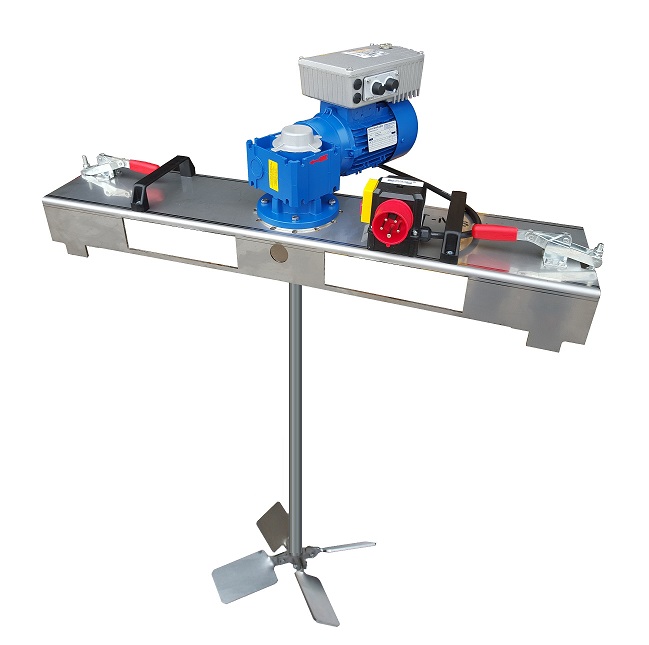

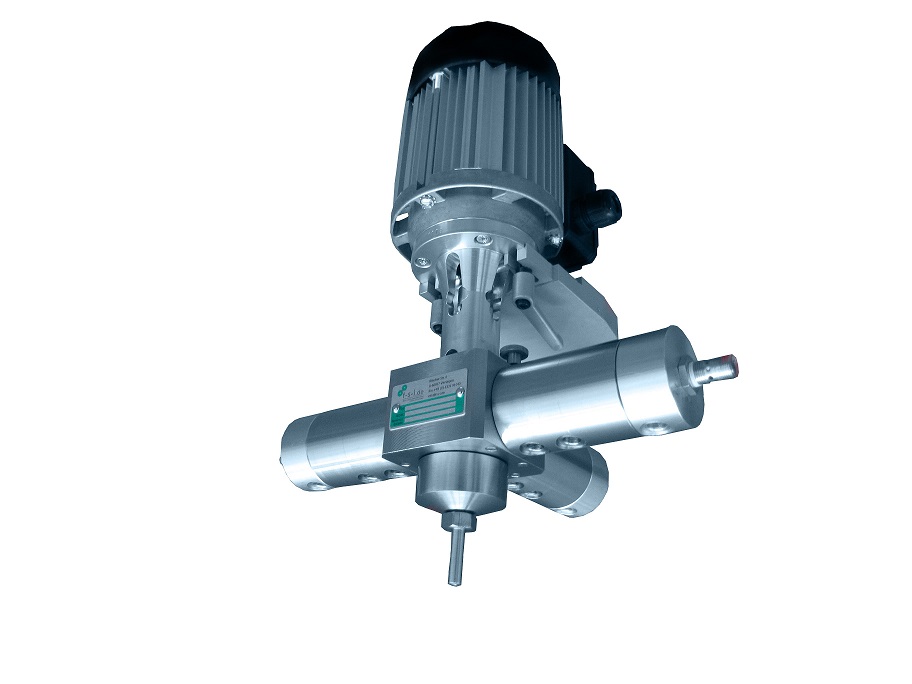

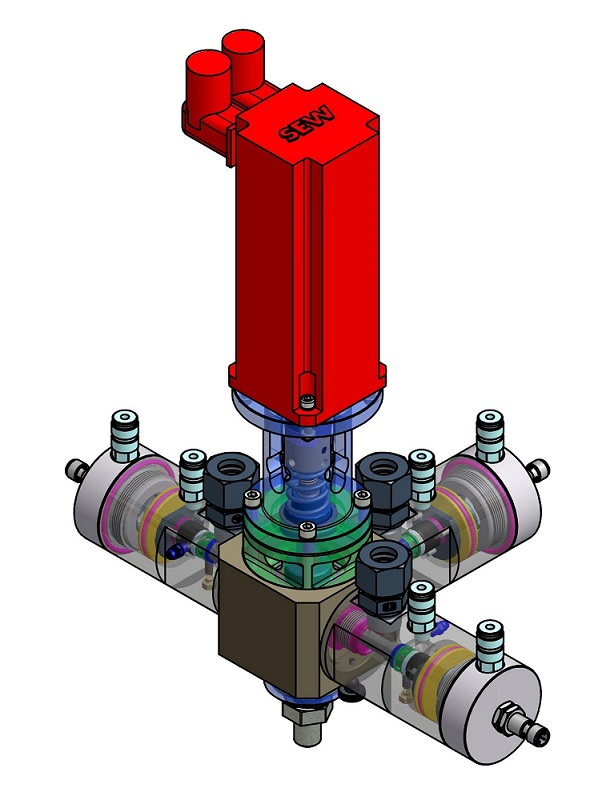

2 component mixing and metering unit with gear pump techology.

The mastermix LV drive is a servo-motor controlled two-component mixing and metering system to process low to medium viscose materials. The systems extreme high accuracy of dosing allows the usage of disposable plastic mixers. Thereby the loss of material due to base purging, as well as the costs for consumables and spare parts, are reduced to a minimum.

Technical data:

- outflow max. depending on material*

- power supply 3 x 400 V + N + PE/ 3.8 kW

- compressed air requirement 6 bar, oil-free, dried, filtered

- dimensions (l x w x h) depending on application

- weight approx. depending on application

*depending on viscosity, temperature, batch of material etc.

Standard equipment*:

- Siemens S7-1500 / touch panel / ethernet-ready for integration in automation

- Software interface is prepared to control automation (standard via Profinet; other interfaces on request)

- dead volume-free construction

- Siemens servomotors

- two gear pumps

- digital pressure sensors

- overpressure safety device

- material shortage control

- pot life control with visual and audible warning signal

- drum shortage control with pump stop

- maintenance free pump sealing system

- variably adjustable mixing ratio

*depending on the application, equipment may differ

Additional equipment:

- material supply system*

- permanent mixing ratio control by volume measuring cells

- additional manual dosage control

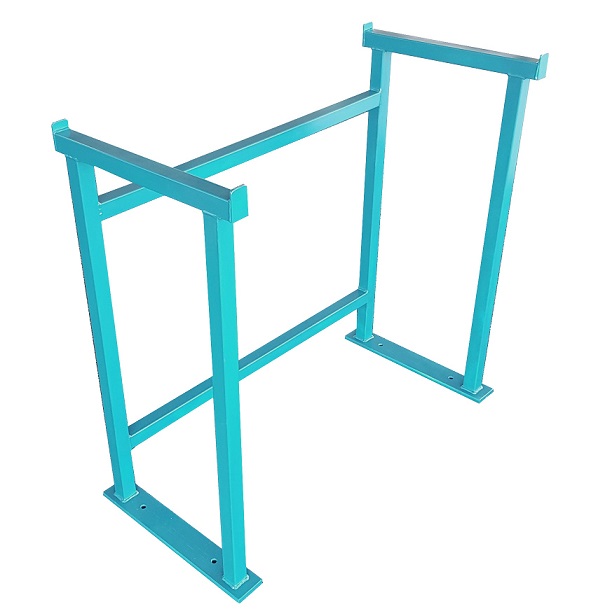

- frames and collecting tanks for drums or IBC-container

- storage tanks in special sizes (depending on application)

- different versions of application units and valves available

* the design of the material supply is adapted to the intended use and to each client individually

more options on request

Data_sheet_mastermix_LV_drive.pdf

Optional_for_mastermix-LV-series.pdf

| Delivery Time: | 8 - 12 weeks |

|---|