Experts in Bonding, Mixing, and Metering

t-s-i.de Misch-und Dosiertechnik GmbH is a German family-run company. At t-s-i.de, we are dedicated to one key mission: absolute reliability. We provide our clients with plant technology for modern adhesive and sealant applications.

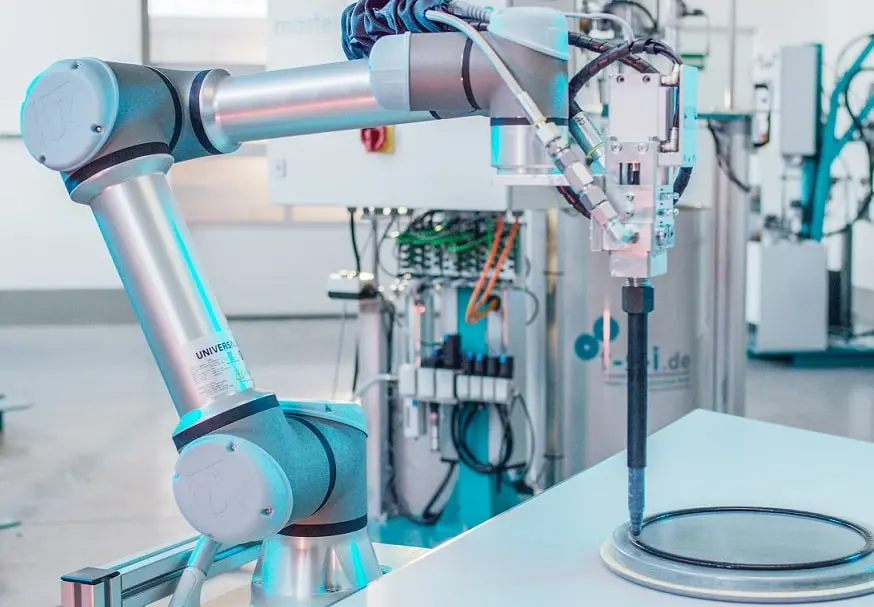

Our services range from engineering standard plant technology to creating tailored end-to-end solutions and the use of robotics. We also offer consultancy, maintenance, and spare parts services.

Bonding or sealing with adhesive dispensers?

Boost your productivity now with mixing and metering machines from t-s-i.de!

Manual, semi-automated, or fully automated application of adhesives and sealants

We offer the right solution for every level of automation.

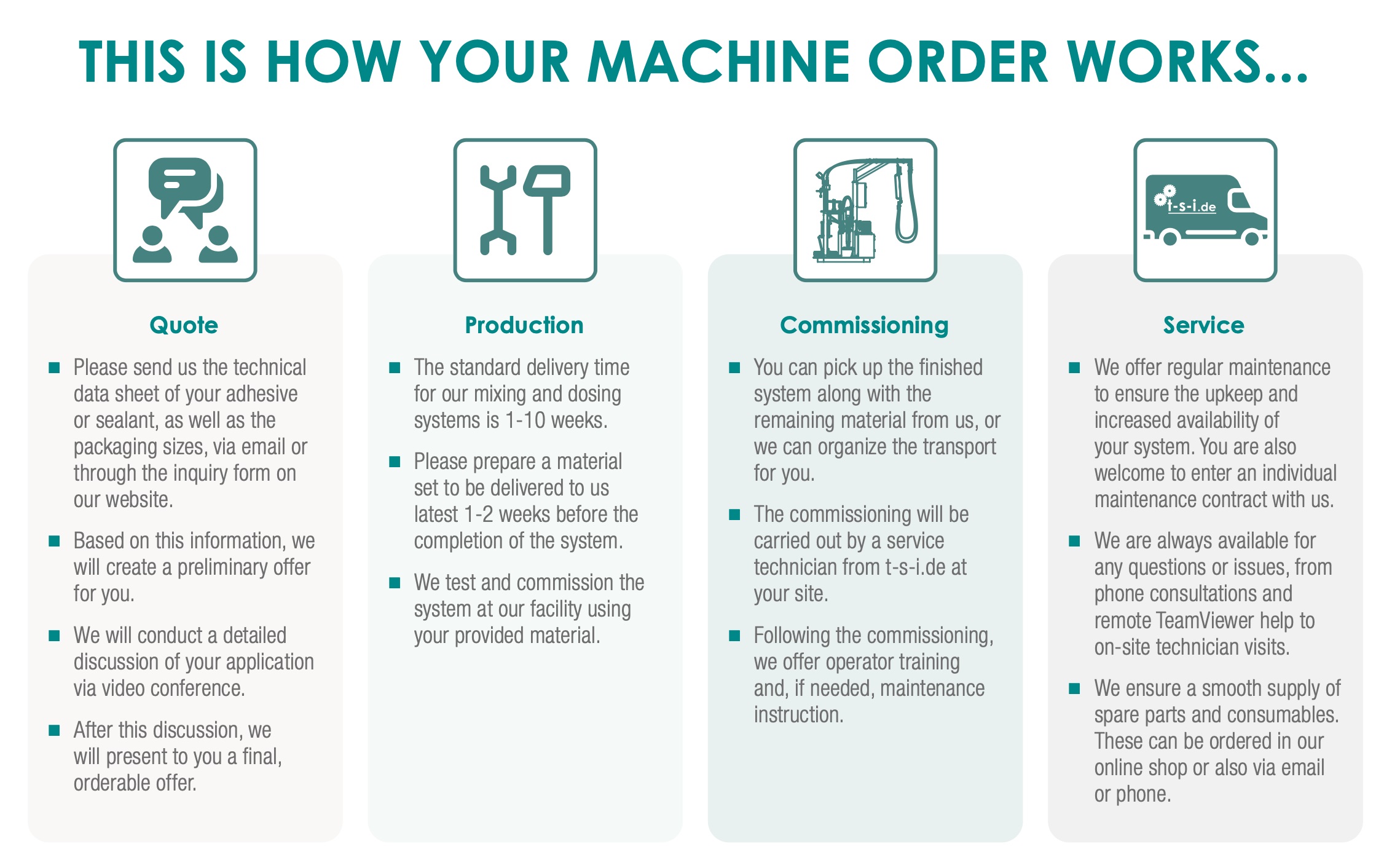

THIS IS HOW YOUR MACHINE ORDER WORKS...

Quote

- Please send us the technical data sheet of your adhesive or sealant, as well as the packaging sizes, via email or through the inquiry form on our website.

- Based on this information, we will create a preliminary offer for you.

- We will conduct a detailed discussion of your application via video conference.

- After this discussion, we will present to you a final, orderable offer.

Production

- The standard delivery time for our mixing and dosing systems is 1-10 weeks.

- Please prepare a material set to be delivered to us latest 1-2 weeks before the completion of the system.

- We test and commission the system at our facility using your provided material.

Commissioning

- You can pick up the finished system along with the remaining material from us, or we can organize the transport for you.

- The commissioning will be carried out by a service technician from t-s-i.de at your site.

- Following the commissioning, we offer operator training and, if needed, maintenance instruction.

Service

- We offer regular maintenance to ensure the upkeep and increased availability of your system. You are also welcome to enter an individual maintenance contract with us.

- We are always available for any questions or issues, from phone consultations and remote TeamViewer help to on-site technician visits.

- We ensure a smooth supply of spare parts and consumables. These can be ordered in our online shop or also via email or phone.

Frequently Asked Questions (FAQ)

How can I place an order at t-s-i.de?

Order easily and flexibly in our webshop, by email, or phone. For retro fans: We even accept orders by fax. We are also happy to create individual offers, especially for larger quantities.

Can I pay for my order by invoice?

Yes, payment by invoice is available. Please contact us for details on this payment method, and we will be happy to assist you.

Are there purchasing options for used plants?

We regularly offer a selection of used mixing and dosing plants. Just contact us! On the other hand, there is also the possibility that we will trade in your used system. For more information, please visit: Buy-Back Offer.

Can mixing and dosing plants also be rented?

Yes, in addition to purchasing, we also offer rental options. For long-term needs, we are happy to develop individual rent-to-own models.

How easy is it to handle the plants?

Our plants are ergonomically optimized and easily integrable into production processes, thanks to our 25 years of experience.

What to do if unsure about the required hose length?

At the initial commissioning, our technicians can bring a mobile hose press, if necessary, to optimally adjust the hose length to your workplace conditions.

Which material manufacturer does t-s-i.de recommend?

As an independent plant manufacturer, we do not give specific recommendations. We advise you to make your choice based on technical quality and economic efficiency.

Which dosing technology suits my application?

Depend on t-s-i.de and our many years of experience for the design. To conceive the suitable plant, we only need the technical datasheet of your adhesive or sealant and the packaging sizes.

What can I do if I have a problem with my mixing and dosing plant?

If you have problems with your plant, we are here for you! Just contact us, and we will help you quickly and competently. Reach us by email at info@t-s-i.de, by phone at +49 (6373) 819980, or use our contact form for quick and easy communication. We look forward to helping you.

What are the main advantages of a mixing and dosing plant from t-s-i.de?

Mixing and dosing plants offer significant advantages: Adhesives and sealants are much more cost-effective in larger containers than in smaller cartridges and foil bags. Additionally, they enable higher dispensing performance, significantly reducing cycle times in production. The monitoring of process parameters ensures a higher quality of the end products. The great advantage of t-s-i.de compared to other manufacturers lies in our excellent customer service and smooth supply of consumables and spare parts.

How long is the delivery time after ordering my new mixing and dosing plant?

Delivery time varies between one week if the plant is in stock, and 6-10 weeks if it needs to be newly produced. In exceptional cases, such as special machine construction projects, the delivery time can be up to 20 weeks. These short delivery times are made possible by our sophisticated modular system, which allows us to customize mixing and dosing plants with standard components for your application.

What training do you offer for operating your plants?

We offer comprehensive training focusing on the operation of the plants, maintenance, and special introductions for foremen to ensure smooth operation.

What does the maintenance and repair service look like?

For acute problems, we offer remote support and on-site technician deployments. In addition, we offer regular maintenance contracts that can be concluded quarterly, semi-annually, or annually, as desired.

Can your plants be integrated into existing systems?

Yes, our plants are ideally prepared for integration into automated systems such as linear systems and robotic cells, both mechanically and in terms of software.

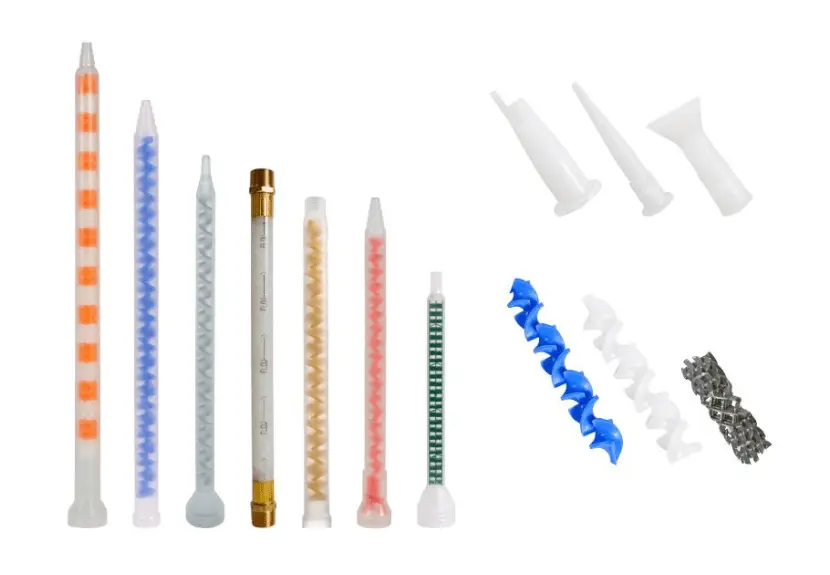

What packaging sizes can be processed on mixing and dosing plants from t-s-i.de?

Machine-compatible packaging includes cylindrical smooth-wall drums, typically 20-liter hobbocks, 200-liter drums, and 1000-liter IBCs. Over the years, we have also developed suitable solutions for processing unusual packaging sizes such as 30 liters, 50 liters, and 60 liters.

Which adhesives and sealants can be processed with mixing and dosing plants from t-s-i.de?

On the more than 2,500 mixing and dosing plants sold by t-s-i.de to date, hundreds of different adhesives and sealants are processed. This includes 1K and 2K systems from various material manufacturers, incorporating technologies such as polyurethanes, MS polymers, silicones, epoxy resins, polysulfide, booster systems, and hybrid systems.