Price on request

Delivery time: 6 - 10 weeks

Product number: 20129-0002-1000

Weight: 114 kg

Pictures may differ from original product

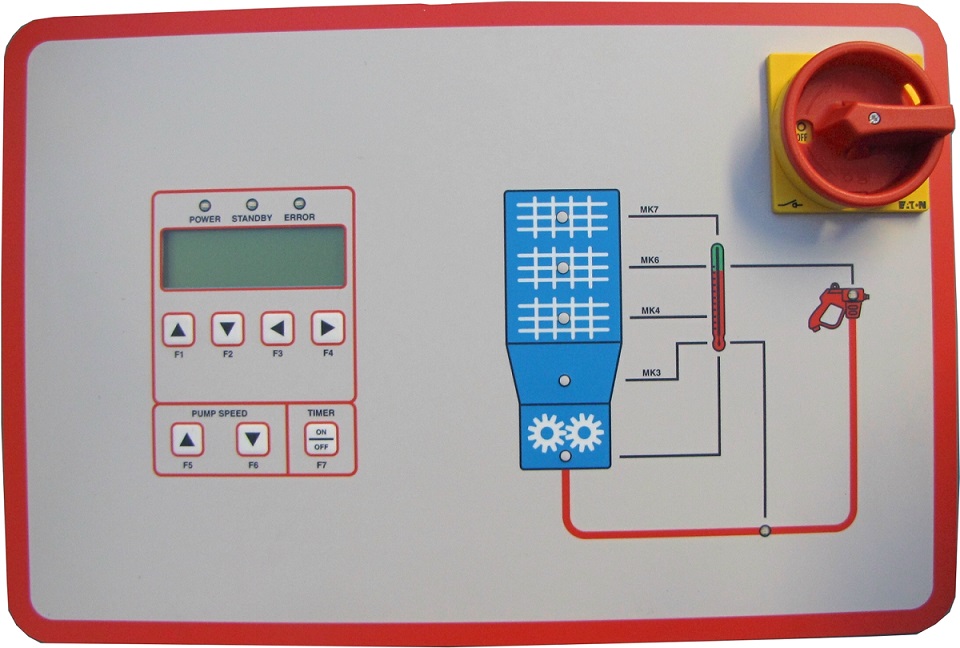

Product information "monoflow HMS 3"

This Hot Melt Extruder is designed to be cost-effective and very easy in sealing of insulating glass units. Almost immediately after the application of the secondary seal the insulating glass units can be processed, due to the material properties of the Hotmelt. The processing parameters of the various Hotmelt adhesives are stored in the control panel and can be selected with the help of a predefined list in the input panel.

Technical data:

- average production approx. 190 units /day

- tank capacity 20 litre

- outflow 0-2 kg/ min.*

- dimensions l x w x h 728 x 380 x 1158 mm

- weight approx. 100 kg

- power supply single phase 220/230V

- electrical power 13Amp/2.3kW

- number heating zones 4 zone

*depending on viscosity, temperature, batch of material etc.

Standard equipment*:

- steel frame, powder coated

- programmable control panel

- temperature control (under/ over temperature)

- material procurement monitoring

- programmable timer for pre-selection of preheating time

- cable-hose assembly with big hose cross section

- low-pressure gun with “Cool-touch” plastic housing

- gun with swivel joint for comfortable handling

- external gun cable fitted outside the cable-hose assembly for easy removal

- robust spiral spring for the protection of the cable-hose assembly

- mobile unit on wheels

*depending on the project, positions can differ

Additional equipment:

- pneumatic clamping table

- handguns for plugging the small gas filling holes

- precision-digital-thermometer

more options on request

Properties "monoflow HMS 3"

| Delivery Time: | 6 - 10 weeks |

|---|