Hydraulic 2-component mixing and metering unit with 2-c gun to use one way mixer.

The mixing and metering units of the mastermix-series are solid and powerful machines, which fulfil all requirements of the processing of two component adhesives and sealants in a superior way. The mastermix XS 2C has been especially designed for materials that could be processed via disposable plastic mixers. Thereby the loss of material due to base purging, as well as the costs for consumables and spare parts, are reduced to a minimum.

Technical data:

- output depending on viscosity, temperature, batch of material etc.

- propulsion A-side hydraulic

- propulsion B-side pneumatic

- power supply 3 x 400 V + N + PE/ 3.8 kW

- compressed air requirement 6 bar, 50 l/min.

- dimensions l x w x h 1500 x 1000 x 1800 mm

- height with swivel arm 2500 mm

- standard swivel arm length 1900 mm

- standard hose length 2500 mm

- weight approx. 600 kg

Standard equipment*:

- Siemens S7-1200 / ethernet-ready for integration in future automation

- optical and acoustic pot life control

- material shortage control

- overpressure safety device

- residual materials optimized following plate

- two hand safety control

- drum shortage control with pump stop

- maintenance free pump sealing system

- dosage control

- variably adjustable mixing ratio

- 200 l A drum / 20 l B drum

- optimized change of 200 litre drum (base plate with recesses for jack lift)

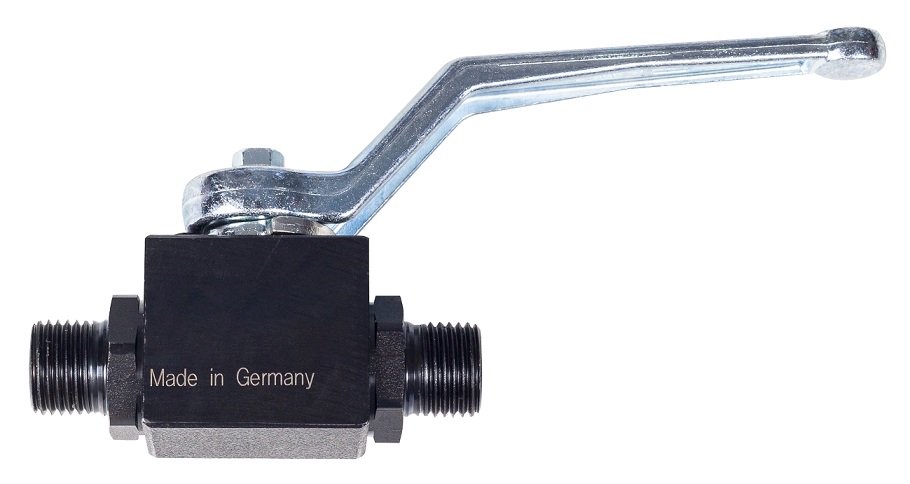

- 2 component mixing valve

*depending on the project, positions can differ

Additional equipment:

- swivel arm prolongation

- swivel arm heightening

- working-hose prolongation

- special painting

- B component pump for 200 l drum

- other drum sizes on request

- following plate heating A-component

- cartridge filling unit (1c and 2c)

- mobile unit, with wheels

- park position with automatic purging

- collecting tank for hydraulic unit

more options on request

Data_sheet_mastermix_XS_2K.pdf

Optional_for_mastermix_series.pdf

Data_sheet_2c_applicator_pistol_system_configuration.pdf

| Delivery Time: | 6 - 10 weeks |

|---|