Product number: 2232-0001-2000

Weight: 650 kg

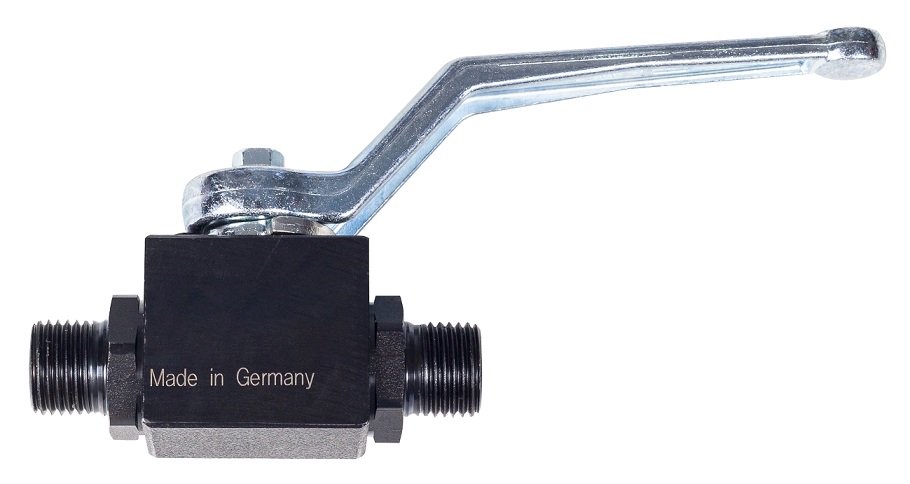

Pictures may differ from original product

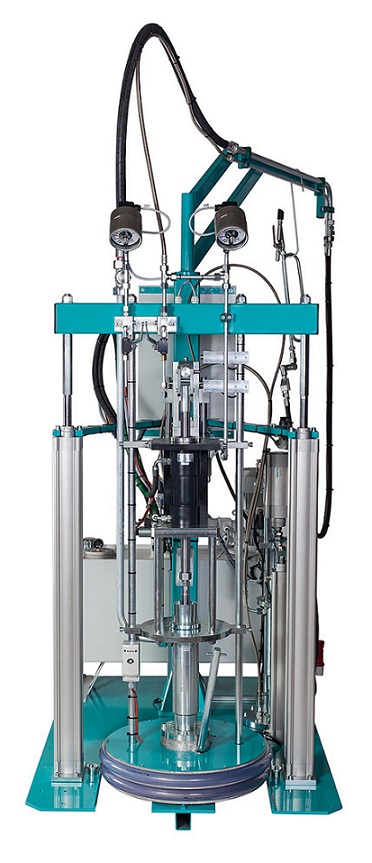

Product information "mastermix XL"

Hydraulic two-component mixing and metering unit

The mixing and metering units of the mastermix-series are solid and powerful high-tech machines. They fulfil all requirements of the processing of the two-component adhesives and sealants in a superior way. By using only selected high quality components of well-known German manufacturers and due to the extensive standard equipment, the mastermix-series live up to the highest grades.

Technical data:

- outflow max. 6000 g/min.*

- A-side powered hydraulic

- B-side powered pneumatic

- power supply 3 x 400 V + N + PE/ 4,5 kW

- compressed air requirement 6 bar; 70 l/min.

- dimensions l x w x h 1500 x 1000 x 1800 mm

- height with swivel arm 2500 mm

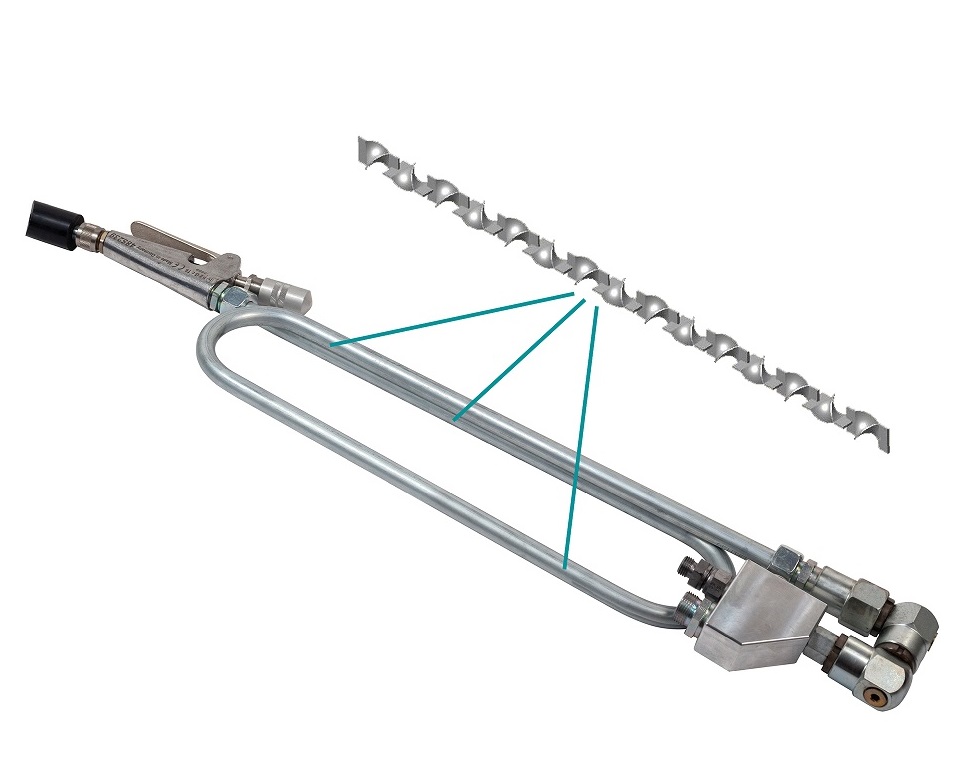

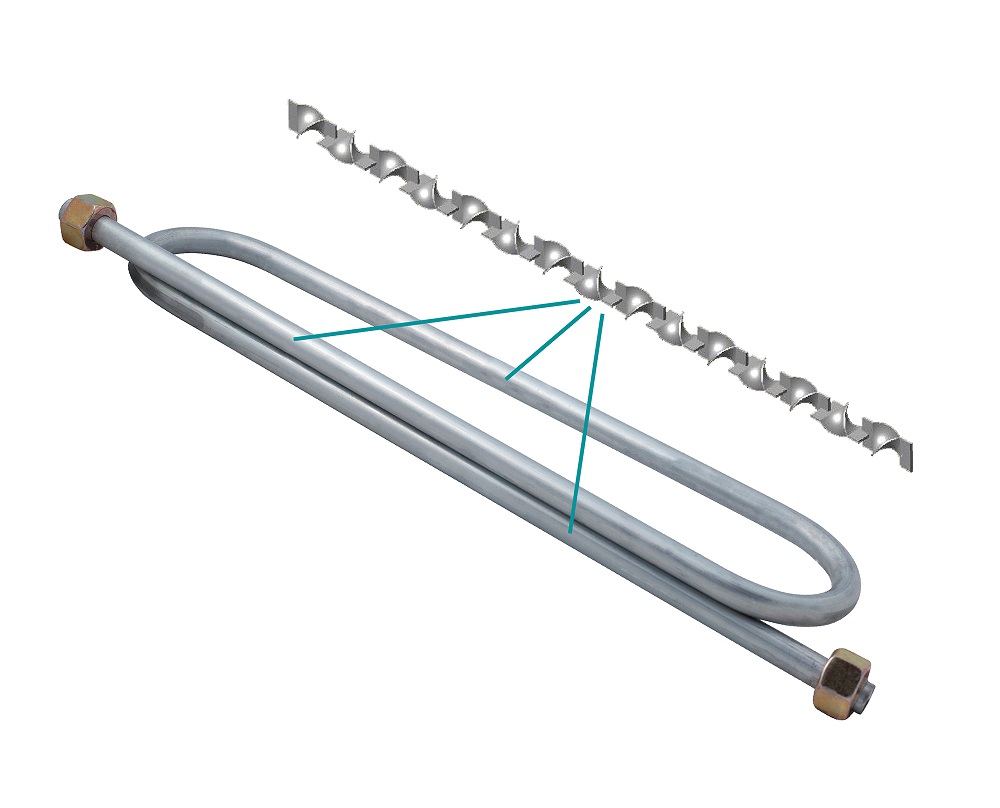

- standard swivel arm length 1900 mm

- standard hose length 2500 mm

- weight approx. 650 kg

*depending on viscosity, temperature, batch of material etc.

Standard equipment*:

- Siemens S7-1200 / ethernet-ready for integration in future automation

- optical and acoustic pot life control

- material shortage control

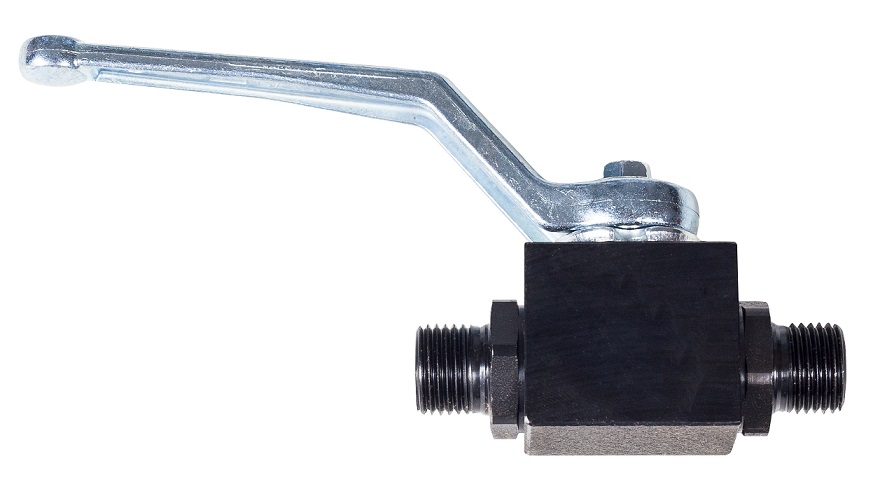

- overpressure safety device

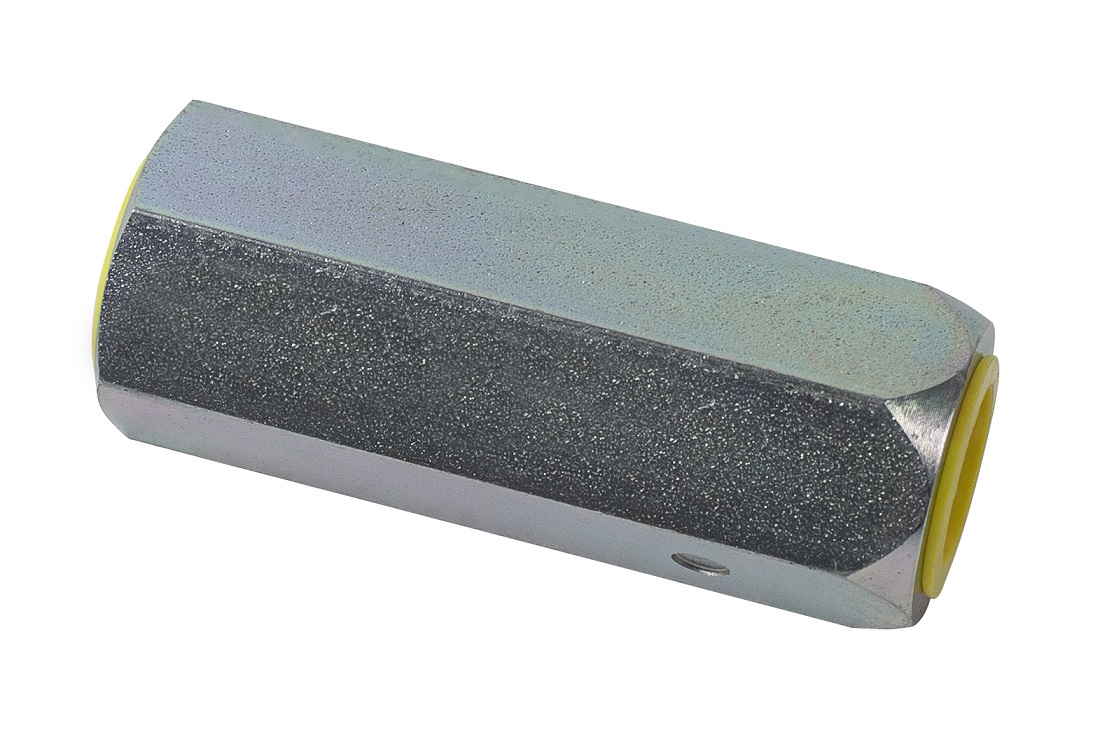

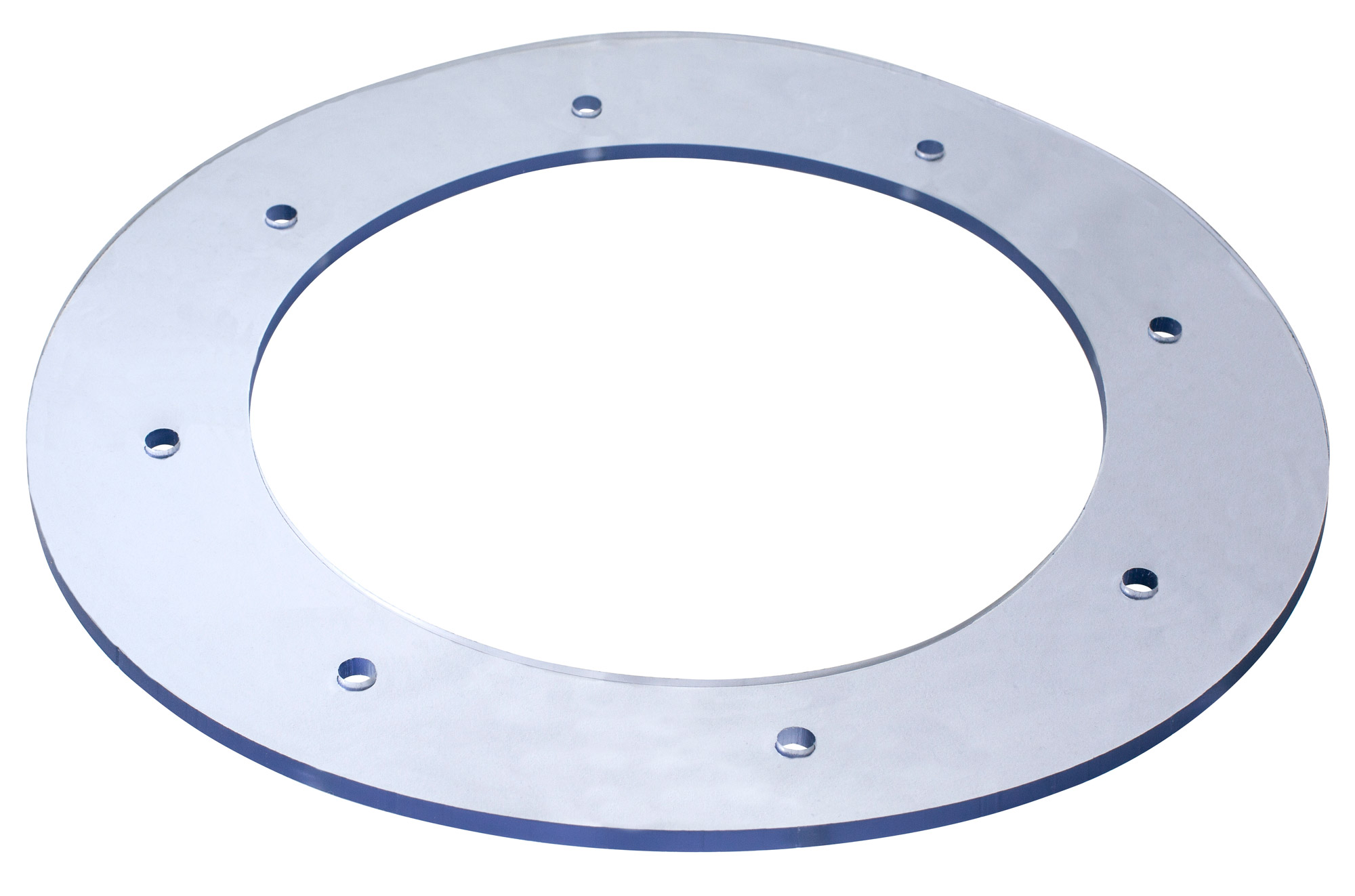

- residual materials optimized following plate

- two hand safety control

- drum shortage control with pump stop

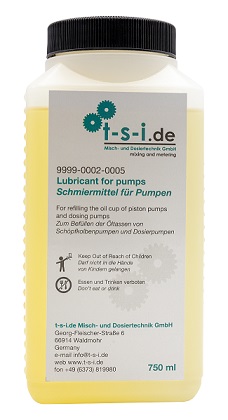

- maintenance free pump sealing system

- dosage control

- variably adjustable mixing ratio

- base purging available

- 200 l A drum / 20 l B drum

- optimized change of 200 litre drum (base plate with recesses for jack lift)

*depending on the project, positions can differ

Additional equipment:

- swivel arm prolongation

- swivel arm heightening

- working-hose prolongation

- special painting

- B component pump for 200 l drum

- other drum sizes on request

- following plate heating A-component

- cartridge filling unit (1c and 2c)

- mobile unit, with wheels

- collecting tank for hydraulic unit

more options on request

Optional_for_mastermix_series.pdf

Data_sheet_accessories_insulating_glass.pdf

Properties "mastermix XL"

| Delivery Time: | 6 - 10 weeks |

|---|